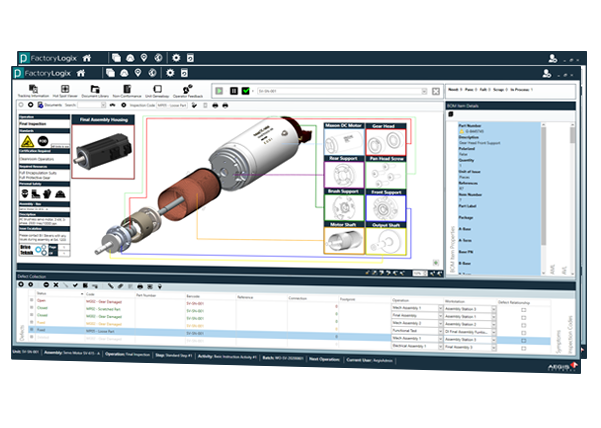

Increasing Customer Satisfaction

Deliver zero-defect products to the best level of customer satisfaction.

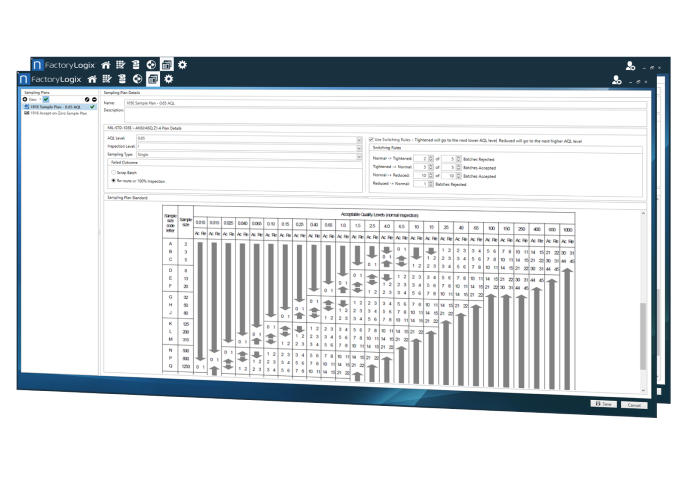

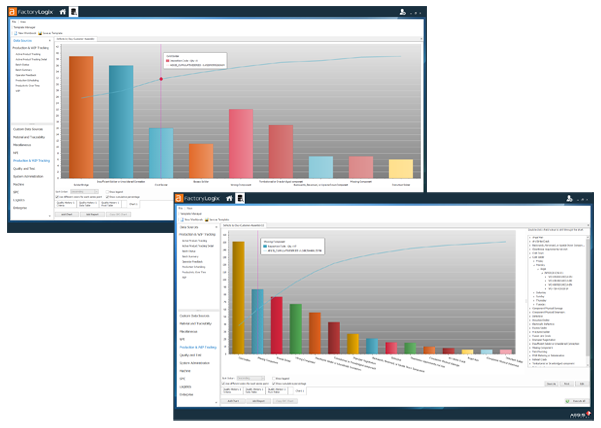

Reducing Quality Management Costs

Convenient and fast guiding quality inspection operation.

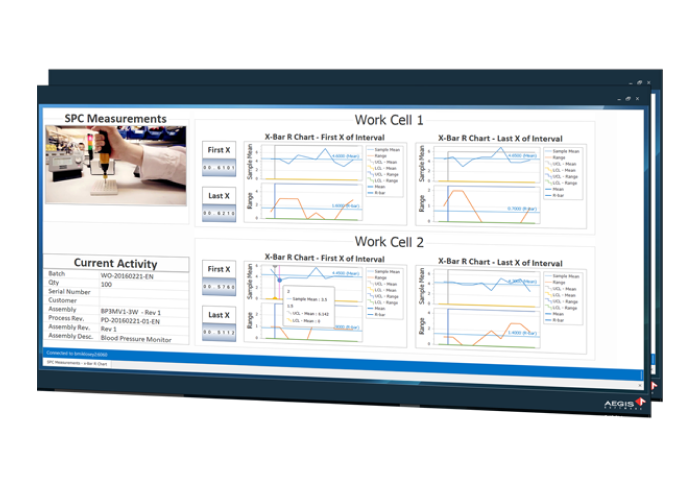

Easier to generate reports

It is easier to generate product conformity reports.

Quality in the whole process of production Zero quality defect

Decrease per million defective products5%

Improved yield

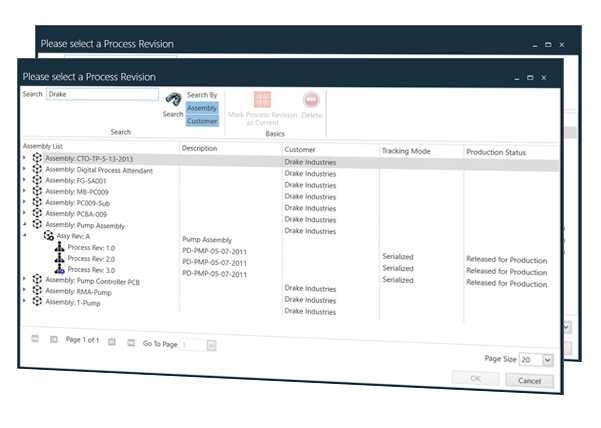

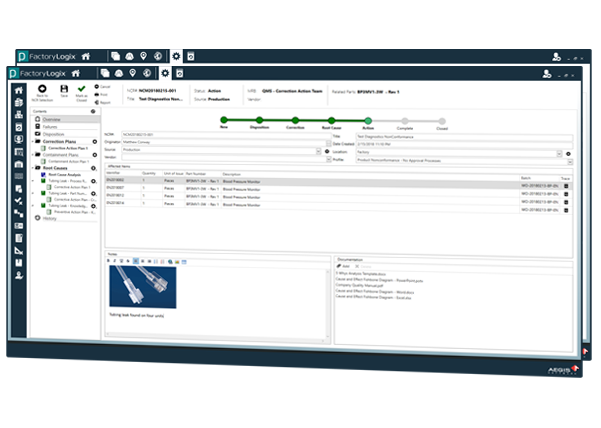

Realize material traceability

Quickly create inspection reports

Decrease30%Assembly rework time

Improve customer response time

Other Customers We Helped