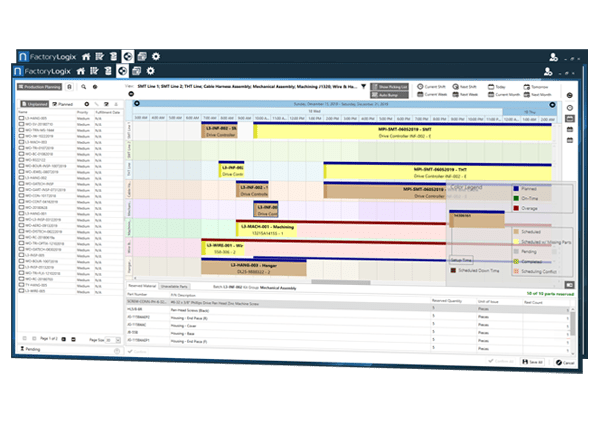

Support small batches and multiple varieties

Facing the complex and ever-changing market demand (small batches and multiple varieties), we support business development through technical means.APSThere are not only relatively simple algorithms, such as the shortest due date algorithm, the shortest working procedure algorithm, but also complex algorithms, such as neural network, simulated annealing, genetic algorithm, tabu search method, etc.

Provide direction for production improvement

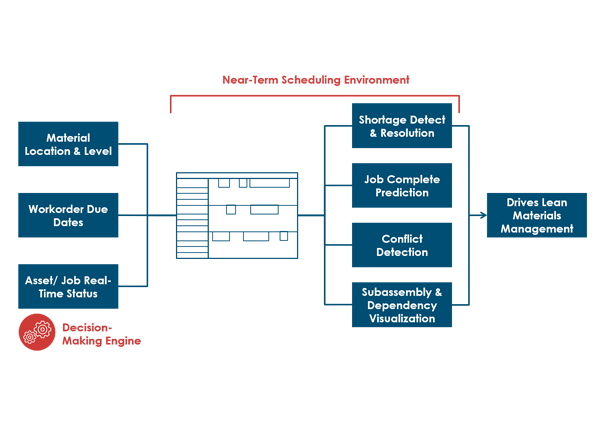

It can correctly predict the manufacturing status and possible problems in the near future. Simulated scheduling can be performed,what-ifAnalysis, that is, if what kind of countermeasures are used, what kind of results can be obtained.

Cost reduction

By optimizing the production sequence and batch size, the time for changing lines and preparation time in the production process are reduced, and energy consumption and material waste are reduced.

Through intelligent scheduling of the maintenance plan of production equipment,APSHelps prevent equipment failure, reduce downtime, and prolong equipment life.

Optimize resource utilization, deduce material procurement requirements, and respond to changing market requirements

Increasing production capacity

Eliminate bottlenecks

Reducing Inventory Costs

Meet delivery schedule

Optimize the use of equipment

Improving profitability

Other Customers We Helped