Cost reduction

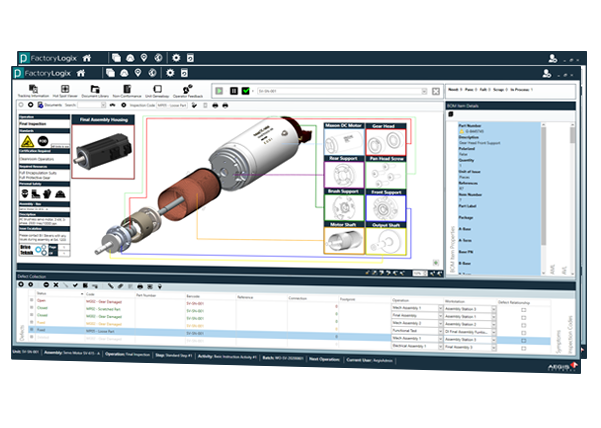

Improve the production efficiency and work attitude of operators, reduce scrapping, waste and defective products.

Improve capacity utilization

According to the continuous production execution data, analyze its laws and defects, and continuously improve the process to improve the standard man-hours.

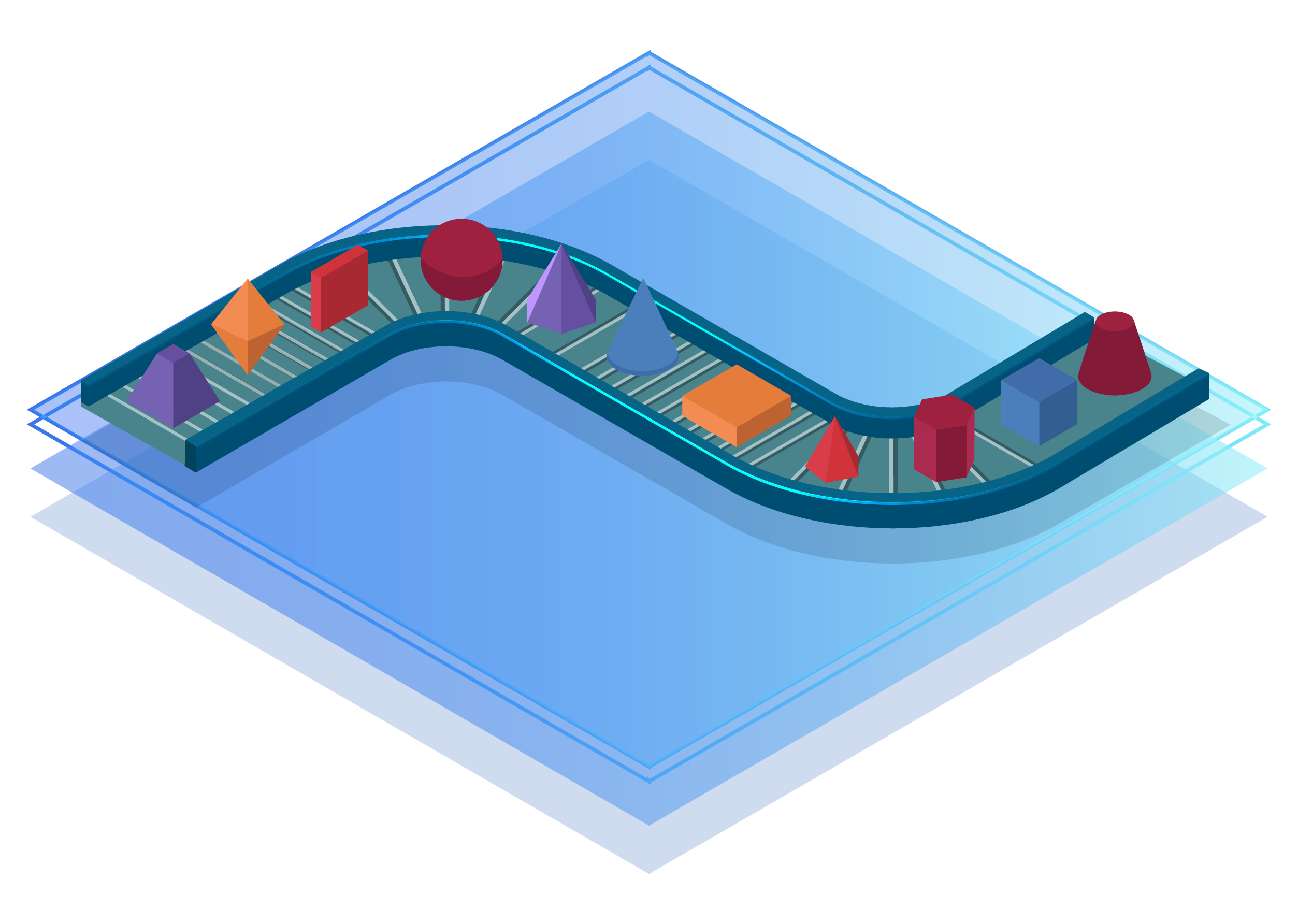

The Process of Achieving Excellence

Improve production efficiency, while promoting continuous improvement and optimization of production processes, increase production, and ultimately ensure more and more stable quality.

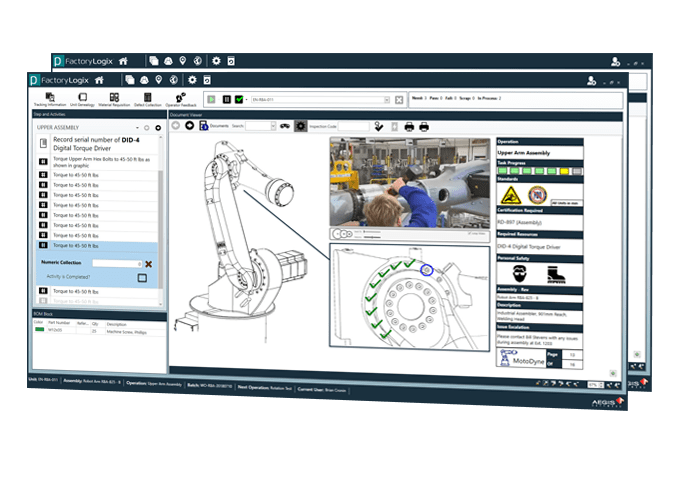

Complete the next stage of production task execution

Reducing unexpected production delays;

Carry out big data analysis based on the data generated by the equipment production process, so as to drive and optimize the production process

Improved agility and flexibility

Solve bottlenecks and imbalances

Supporting Data Compliance and Security

Eliminate unreasonable capacity utilization caused by unreasonable production scheduling

Other Customers We Helped