Safety Stock Guarantee

Automatically calculate the safety inventory to ensure that the inventory level is always within a reasonable range; At the same time, the system can also intelligently adjust the inventory quantity according to historical data and forecast models to avoid excess or shortage.

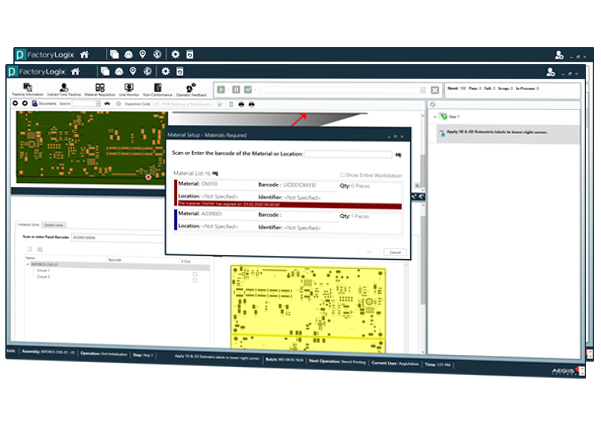

Material Quality Assurance

Carry out quality inspection and verification of raw materials and parts provided by suppliers. The module covers the collection, analysis, reporting and traceability of incoming material quality data to ensure that incoming materials meet quality requirements and provide real-time quality indicators and reports.

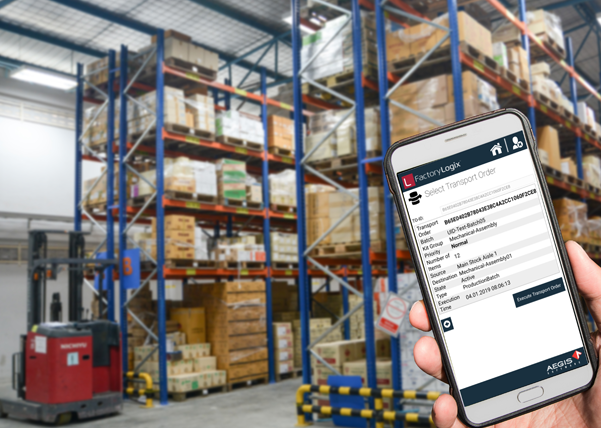

Inbound and Outbound Response Time Guarantee

According to work order/Order information, inventory, goods attributes and other factors to formulate an appropriate picking strategy. Common picking strategies include picking by order, picking by batch, picking by wave, etc., to improve picking efficiency.

Reduce labor costs,Improve work efficiency.

Improved quality and reliability;

Complete material traceability

Facilitating compliance/Consistency

Speed up response time

Optimizing Plant Utilization Ratio

Improving Customer Satisfaction

Other Customers We Helped