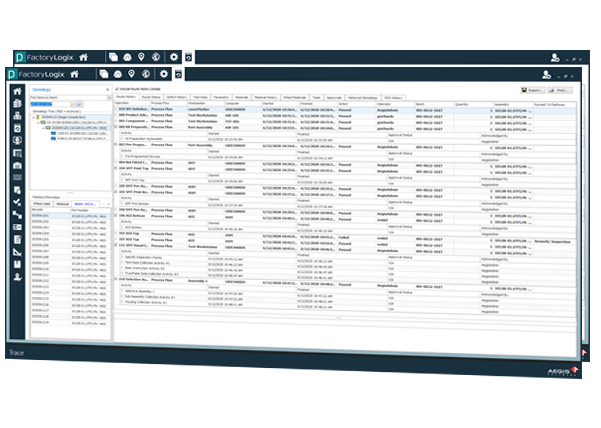

Establish a long-term mechanism for equipment management

Standardize the establishment of spot inspection, maintenance and repair systems for equipment.

Improve equipment utilization

Diagnose the operating rate and operating rate of the equipment through data acquisition.

Reduce equipment failure rate

The knowledge base files established by daily maintenance can effectively prevent failures.

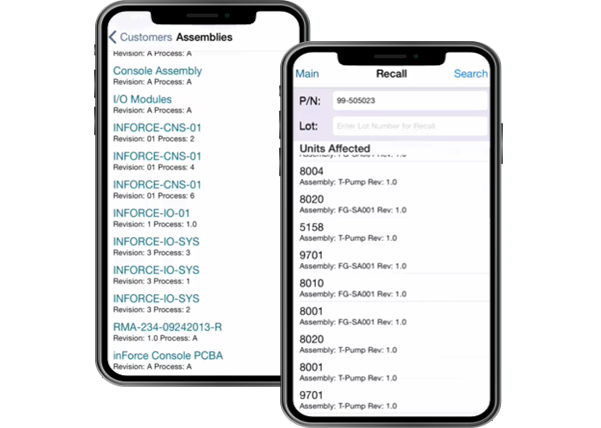

Accelerate, simplify, and control the entire life cycle of a product;

Increasing business opportunities;

Improving Customer Satisfaction

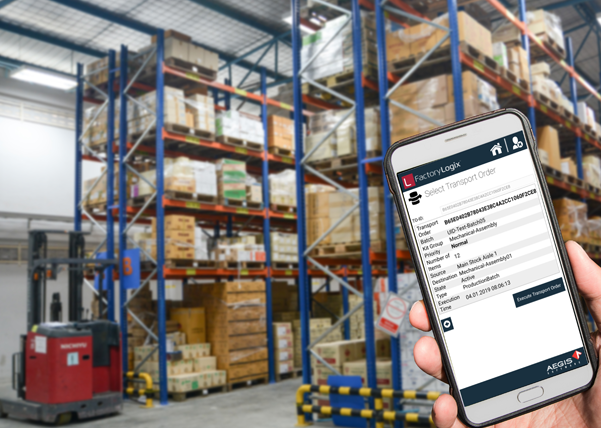

Eliminate inefficiencies

Reducing material costs;

Reducing Liability Risk

Increasing visibility;

Other Customers We Helped