Predictive maintenance

Overtake75%Of equipment and system failures occurred without notice. Resorted toIIoTPreventive maintenance combined with analysis to predict machine failure.

Manufacturing process optimization

Equipped with sensors and usingIIoTSystems-managed machines and equipment can monitor conditions, equipment, and workflows, such as machine performance, assembly line management, supply chain optimization, labor safety, or quality assurance processes, for optimization.

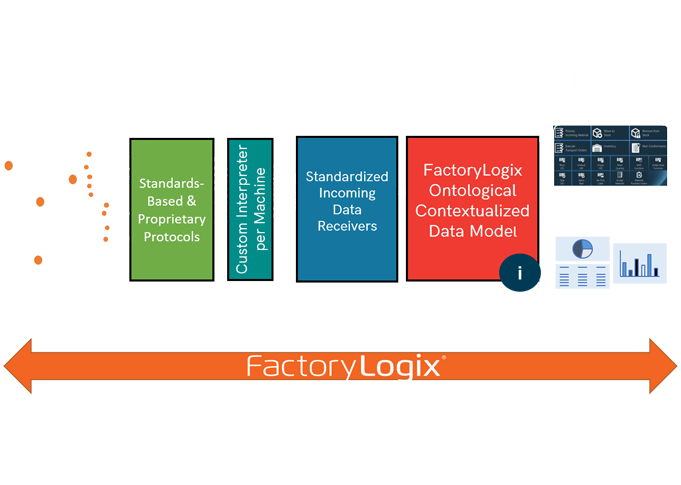

Production system perception and monitoring

IIoTAt the heart of the solution is continuous communication between the system and the machine to ensure optimized throughput and identification of machine defects in real time.

UseIIoTCan revolutionize production

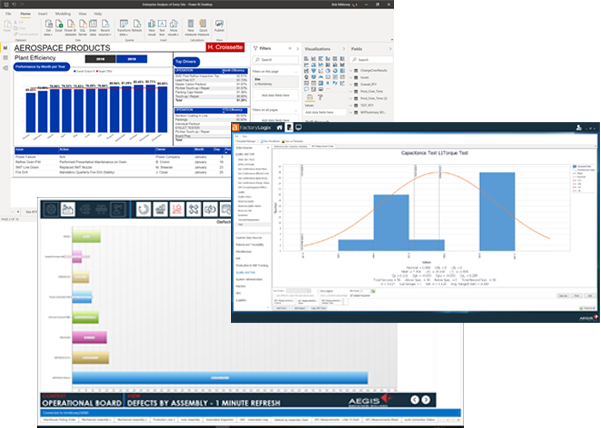

Acquire100%Operational visibility

Adding Value from Data

Real-time industryBI

Cost reduction

Industry4.0Implementation of

Reduces the cost of accurate tracking;

Other Customers We Helped