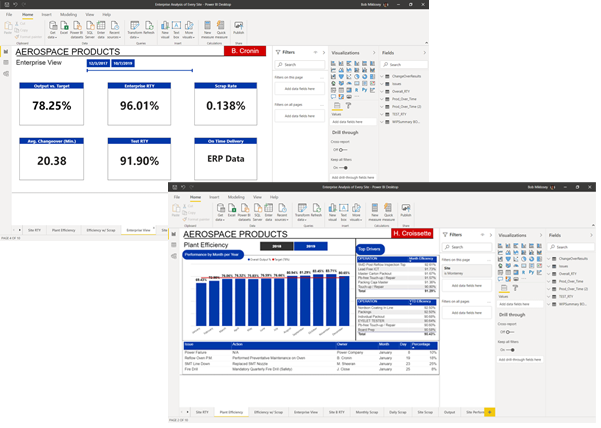

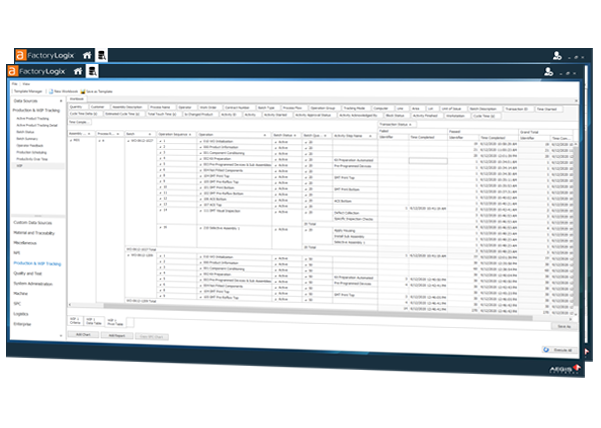

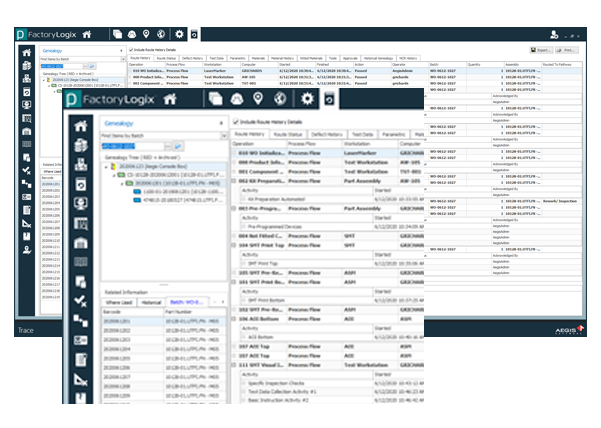

Real-time reflection of production status

Operators can quickly understand the production progress and product quality through the electronic kanban, discover and solve production problems in time, and ensure the smooth progress of the production process.

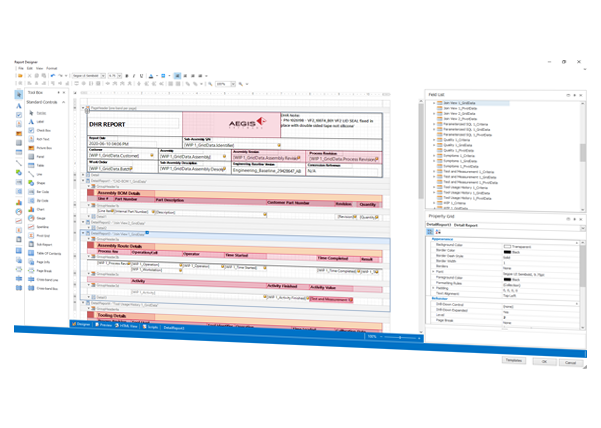

Data Sharing and Traceability

Real-time data transmission to relevant systems inside and outside the enterprise, real-time data sharing and traceability will help enterprises better understand market demand and competition conditions, as well as grasp the operation of the entire supply chain.

Improve the efficiency of information transmission

Compare real-time data with historical data to help production teams understand production conditions and trends, predict and analyze future production needs.

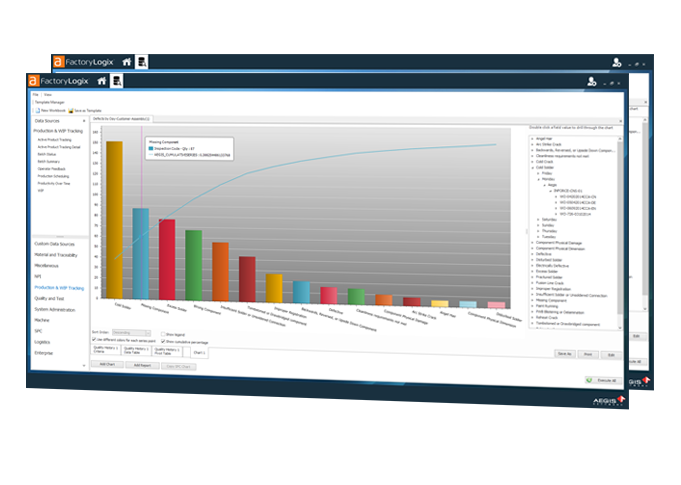

Deeply mining production data to promote intelligent decision-making

Simplify decision-making

Improving quality

Improve machine utilization(OEE)

Process optimization

Reducing Inventory Costs

Improving profitability

Other Customers We Helped