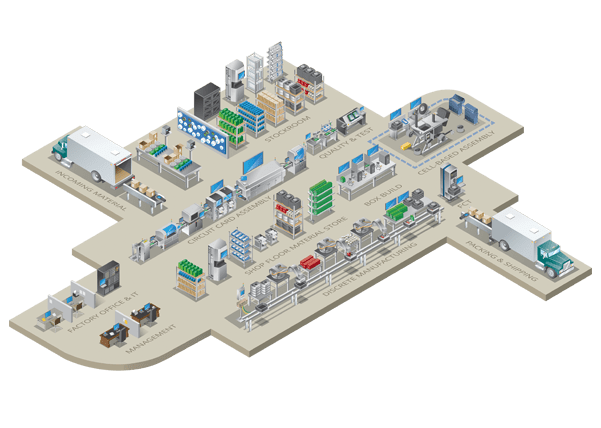

Optimize operations across multiple systems

Multi-system collaborative operation to meet business production needs.

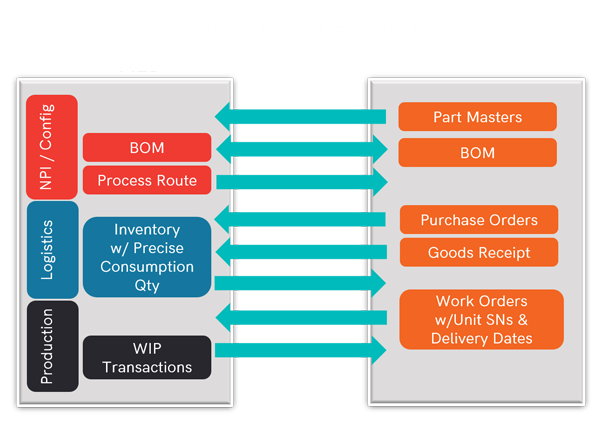

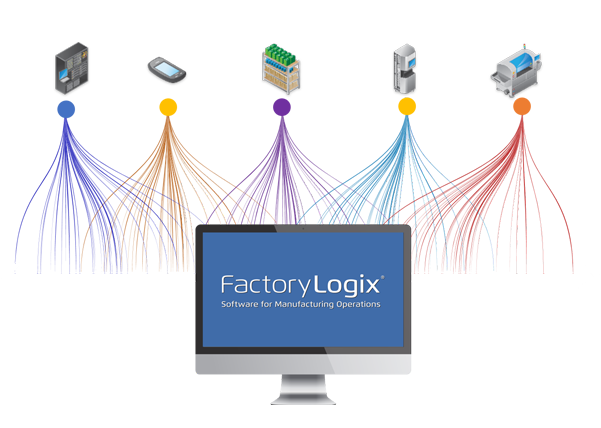

Low-cost and low-risk integration

Extensive use of standard technology to achieve data docking.

Integration adaptation integrity

Adapt to a variety of different business systems.

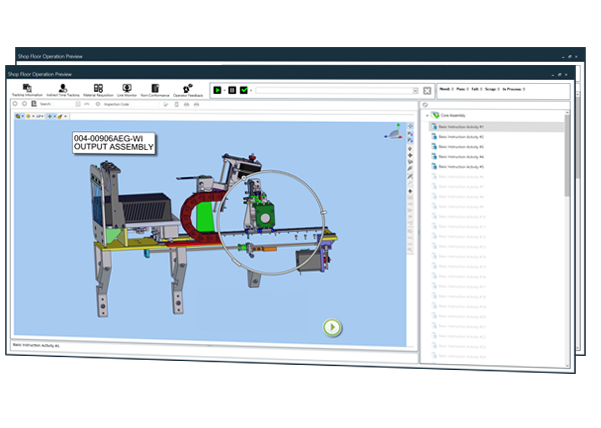

Improving businesses;ITInvestment Strategy, Decision Making and Compatibility

Reduce integration costs

Better compatibility

LoweringITCost and support

Utilizing standard techniques;

Service Oriented ArchitectureSOA)

Reduce the risk of interaction between systems

Some of the other clients we've helped